1) What is this?

2) Why does the pulley suck to begin with?

3) What are the current methods of dealing with the pulley?

4) Why might these methods suck?

5) My method, explained and demonstrated

6) Conclusion

This write-up is a little more comprehensive than originally intended. If you already know all about the shortcomings of the '94 Accord alternator pulley, feel free to skip right to the meat, which is section 5.

Let's begin.

1)

This is a write-up that examines some of the problems associated with the ’94 Accord alternator pulley and outlines what I consider to be an easy solution for those who wish to remedy those problems. Of course, just because I find it easy doesn’t mean you will. Please bear in mind that this write-up is really long and horrible, and you might hate it if you don’t like reading long, boring, shitty write-ups that could probably have been explained in just a few sentences.

2)

First of all, let’s quickly review why exactly the ’94 Accord alternator pulley sucks just in case you don’t know anything about it. The stock third gen alternator pulley has only five grooves. The ’94 Accord pulley has six grooves. As a result, the ’94 Accord pulley sticks out a little bit farther to the right than the stock third gen alternator pulley does. This creates a clearance problem between the outer end of the alternator pulley and the power steering belt. This clearance problem is the whole issue with the ’94 Accord pulley.

3)

Now let’s talk about some of the current methods of dealing with this little problem. The first thing that comes to mind and the method that makes the most sense is to just replace the ’94 pulley with the right one. Apparently, the stock third gen alternator pulley won’t fit without first doing some work to it, so we can forget about that one for now. The best pulley for the job is the ’90-’93 Accord alternator pulley. From what I’ve read, it goes straight on the ’94 Accord alternator with no problems.

The other method I’m aware of involves moving the power steering pump out a little bit from its mounting bracket. Essentially, you are eliminating the contact between the ’94 Accord alternator pulley and the power steering belt by having the pump sit just a smidge to the right. This movement is achieved through the use of washers on the power steering pump mounting bolts, on the bracket side of course. This method encourages you to stick one, two, or however many flat washers on either of the two power steering pump bolts, however many is required in order to eliminate the contact described beforehand.

4)

There are some potential problems with these two methods. Obviously if you aren’t able to find a ’90-’93 Accord alternator pulley, this first method isn’t going to work for you.

I don’t really like the washer method, and I’ll tell you why. When you offset the pump in this manner, you’re offsetting the belt as well. The belt still rides along the crank pulley and the idler pulley just as it normally would. When you offset the belt, you put tension on either side of the belt. In the big picture, this can shorten the belt’s life. Obviously, the more washers you stick in there and the farther out the pump sits from its normal position, the more you’re stressing the belt and the harder it has to work to stay on and do its job. Also, we shouldn’t be too quick to dismiss the extra stress we might be putting on the power steering pump by doing this, not to mention the idler. I say this because I had the idler pulley come loose on me not long after I had done the washer trick here. It might have been a complete coincidence. I really can’t say.

Yes, I might be exaggerating a little, or perhaps even making something out of nothing, but really, moving your power steering pump over with washers isn’t the way to take care of this problem. It is only a band-aid, a temporary solution until you actually eliminate the problem altogether.

So, the current solutions might not work for you. One of them requires you to secure a part from another alternator, and the other one, while a great temporary fix, just downright stinks for the long term. It might not actually stink: I just don’t think it’s all that great for the belt or for the pump.

5)

Here is what I propose: I propose shaving the pulley to remove the excess length thereby eliminating the clearance problems.

Say what?

Here is the part of the write-up where I show you what to do and how to do it. It’s really not complicated. I must, however, point out that I am doing this demo on my stock third gen alternator because I already did this on my ’94 Accord alternator. It really doesn’t matter what alternator I do this on, though. I’m only doing this to give you folks an idea of what I’m trying to accomplish here.

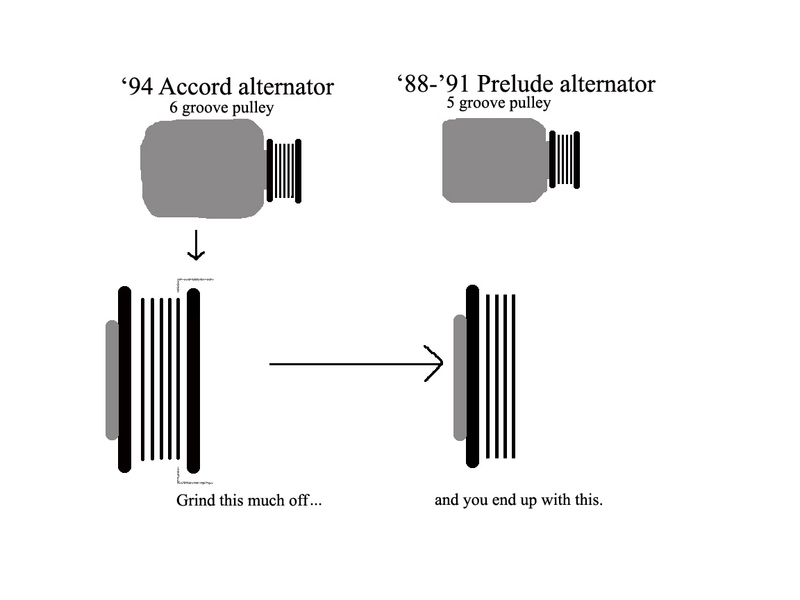

Here is a diagram I made. It simplifies what we’re doing and shows you exactly what we’re going to be removing from the pulley and what the pulley will look like when we’re finished grinding:

Please excuse my horrible drawing skills.

To do this job, you need an angle grinder or pneumatic equivalent (which everybody has, right!?), a ’94 Accord alternator with pulley, a flat, stable surface (kinda like a work bench), and a means of securing the alternator to the table/bench/whatever you’re using.

When I did this, I used a C-clamp to hold the alternator to my picnic table. The best way to clamp the alternator, I think, is to set it up so that the pulley is perpendicular to the surface you’re working on. You don't have to go ape on it. Just make sure it won't fly off the table when you start grinding it.

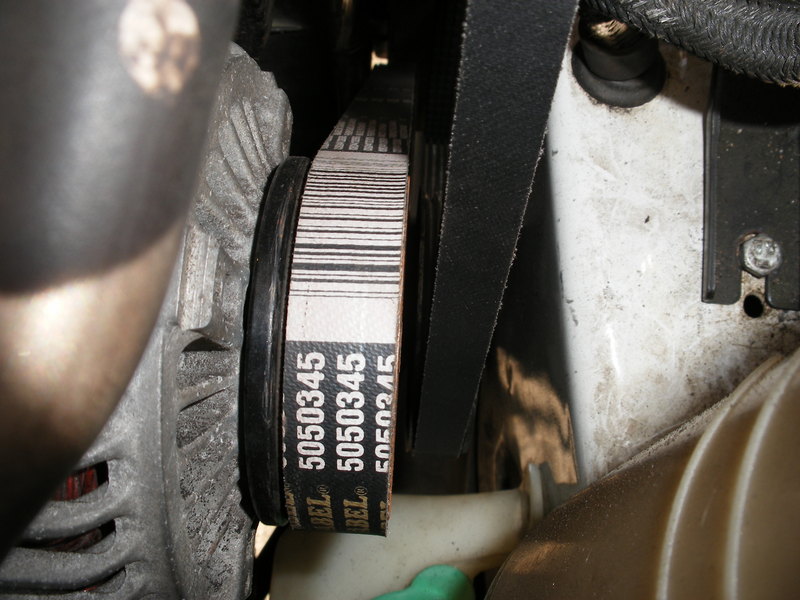

Here’s how I had mine:

Because we’re grinding, I recommend wearing some sort of eye protection. Hearing protection won’t hurt either. Some sort of respirator with a built-in face shield would be totally awesome for this, not that you're going to be breathing in a whole lot of crap. We don't need to go insane with this, but better safe than sorry, right? The bare minimum is safety glasses.

Throw a rag over the case of the alternator to ensure that metal particles and dust and shit don’t get in there. That’s not what you want. Make sure the rag won’t get caught up in the pulley somehow. I recommend a rag because depending on how long this takes you, the alternator might get a little toasty from having its guts spinning around. A plastic bag might not be the best thing for this job because, duh, it might melt. Whatever you use, secure it so that the pulley won’t grab it and try to take it for a walk.

When we start grinding the pulley, we want to hold the angle grinder so that the disc is perfectly parallel to the face of the pulley, kinda like this:

To obtain a nice smooth finish, it would probably be best to let the alternator spin freely while you’re doing this. If you don’t let the pulley spin freely while you’re grinding, the shaved surface might be wavy when you’re done, and that just doesn’t look good. Just ‘cause we’re performing surgery on this thing doesn’t mean it has to look like dildos after.

In order to make sure you don’t grind too much material off the pulley and turn it into a boat anchor, I recommend wrapping some masking tape or something around the pulley. Have the tape begin at the point where you want to stop grinding. This is just like when you tape a drill bit before you drill a blind hole. It’s not mandatory but it will prevent you from making a huge mistake. If you take too much off, you can’t exactly put it back on, so pay attention to what you’re doing if you don’t feel like doing the tape thing. Remember: we want to keep five grooves in the pulley. Really all we’re doing is just grinding the big lip off. With the lip gone, we should have enough room to clear the power steering belt. You can take off just a little bit more as per my diagram, however.

You definitely want to keep the grinding disc away from the middle of the pulley where the end of the shaft is, like this:

You don’t want to end up grinding part of the shaft away, not like it really matters that much, I guess. You might not end up getting close to it at all, but stay away from it just in case.

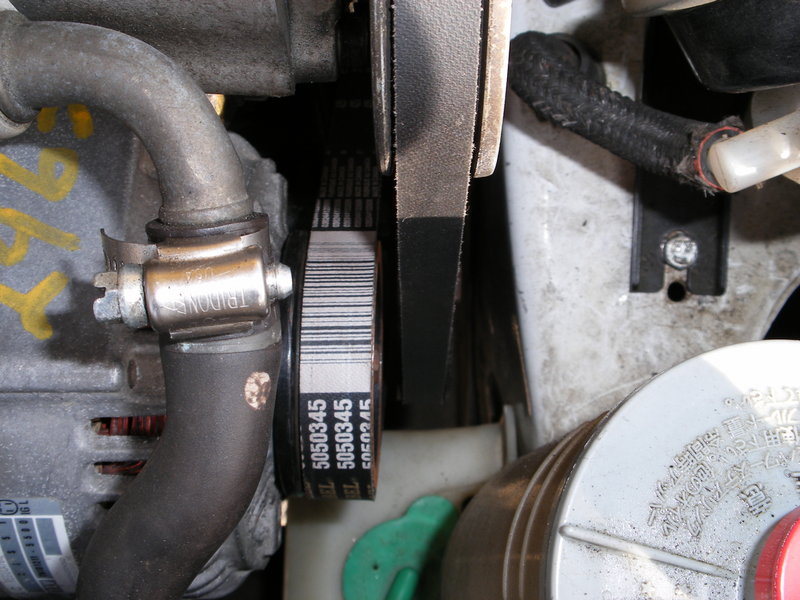

After grinding for a while, you should end up with something that looks like this:

Are you seein' this shit!? Seriously, my camera rapes cold hard fucking ass.

As you can see, I took off the lip and a little bit more. I did exactly what I showed you in that diagram, actually. I wanted to make damn sure that there was no clearance issue when it was finished and that I’d only have to do all this once. I think you could get away with just grinding the lip, though.

6)

18 pages of shit later, and that’s all there is to it. Now I know what you’re thinking.

Tuna, is this safe to do?

Tuna, is this going to make my belt shit a brick?

Tuna, what’s an angle grinder?

Tuna, am I gay!?

The answer is yes, it’s perfectly safe. I did this last spring/summer-ish (I think!?) and have had absolutely no problems with the alternator belt, the alternator, the adjustment bolt or any of it. If you asked the alternator, it’d probably say “What pulley shave? What material gone? I don’t know what you’re talking about, but lately I’ve had a spring in my step. It feels as though I’ve lost that stubborn belly fat I was always so ashamed of.”

I waited to do this write-up just in case something might hiccup, and nothing out of the ordinary has occurred. Now, I’m telling you folks about it because I believe it is safe to do. It has the Import_Tuna seal of approval. I call it the Import_Tuna Totally Awesome ’94 Accord Alternator Pulley Shave, and hopefully it will earn your seal of approval as well.

Any questions? Hopefully you found this helpful and not long and dreadfully boring. Anyone with arms and an angle grinder can do this little trick. It doesn’t take very long, and it offers a permanent solution to the clearance issue that we’ve all hated for so long. Well, I hated it for a little while.

Lastly, I take no responsibility for any harm that might come to any person, animal, or object as a result of attempting this job. If you fuck the whole thing up and get AIDS and die, don't come crying to me about it. As long as you understand what you're doing and take some simple safety precautions, you won't fuck this up.

--J